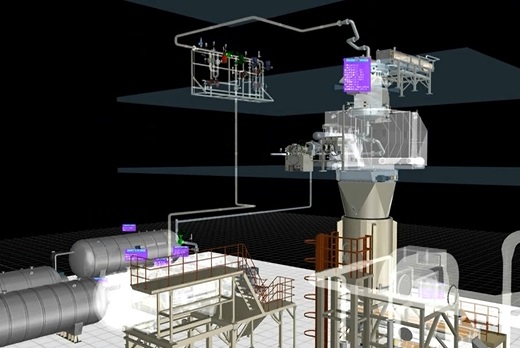

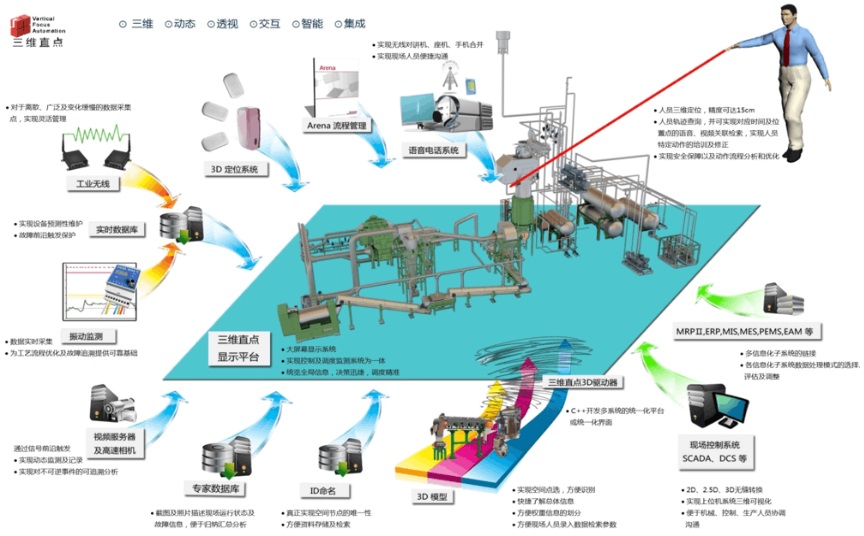

VizArena platform

Three-dimensional real-time interaction, multi-model management. Customized interfaces, be able to integrate with various systems including: Management systems such as ERP, MES, and SAP Control systems like SCADA, PLC, and DCS Video surveillance systems and positioning systems etc.

Augmented 3D context design based on lean management thinking

Augmented 3D context is designed and built according to the enterprise management level, management area, and management positions Quick switch among multi-context, context-based events data push and feedback.

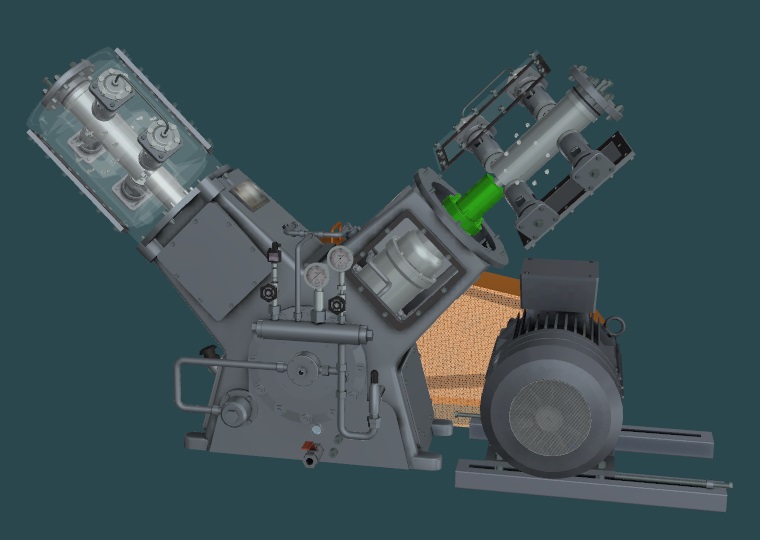

Augmented 3D model & real-time rendering

Equipment composition structure based “direct point and select” operation and hierarchical operation. Model display attributes are dynamically adjusted. Support real-time rendering of large scenes constructed with 100,000 independent models.

Augmented 3D context animation & virtual simulation

Simulation of production process, equipment motion, material status. Supporting simulation driven by real-time signals. Supporting virtual SOP guiding simulation.

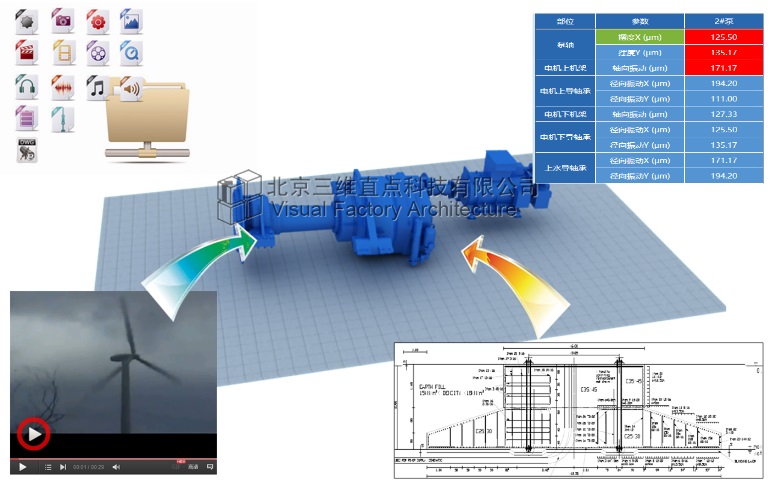

Online data & offline data

With online data connection, the data displays in the 3D contexts, the alarm displays using the highlighted 3D model with camera position. Offline data such as various manuals, reports, drawings, photos can be managed by the corresponding 3D models.

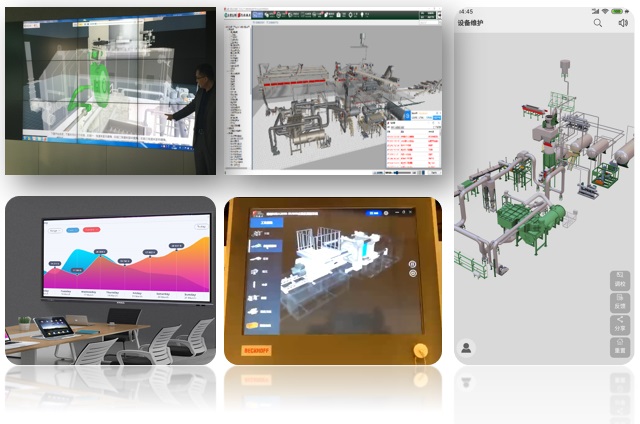

Multi-terminal support

Provide terminals according to the application purposes. Supporting both C/S, B/S architecture, public cloud, private cloud deployment.There are five types of terminal for:

- Large screen

- Conference screen

- PC

- HMI

- Mobile terminal